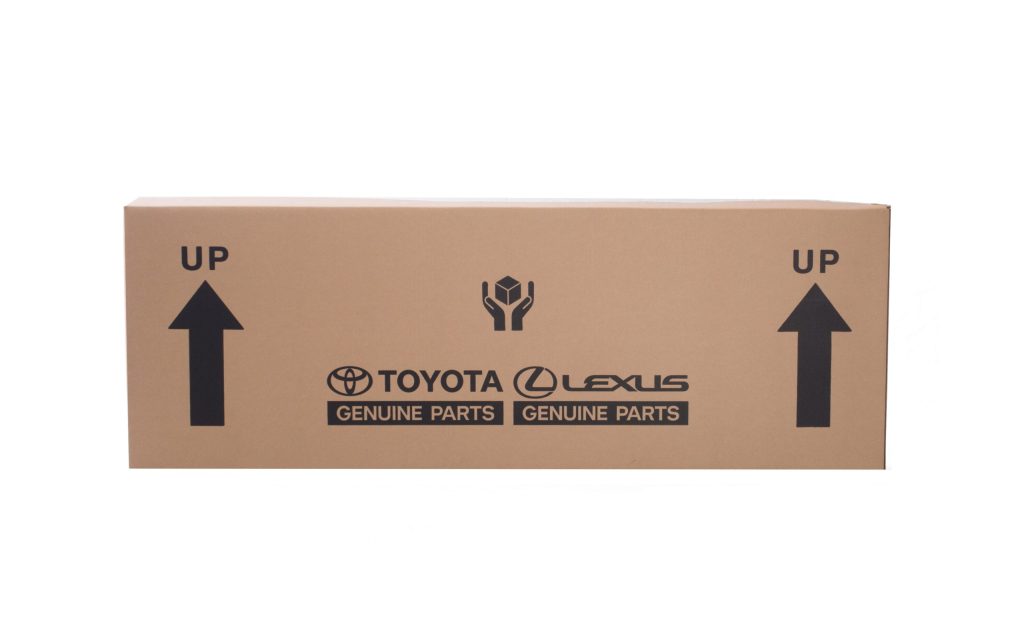

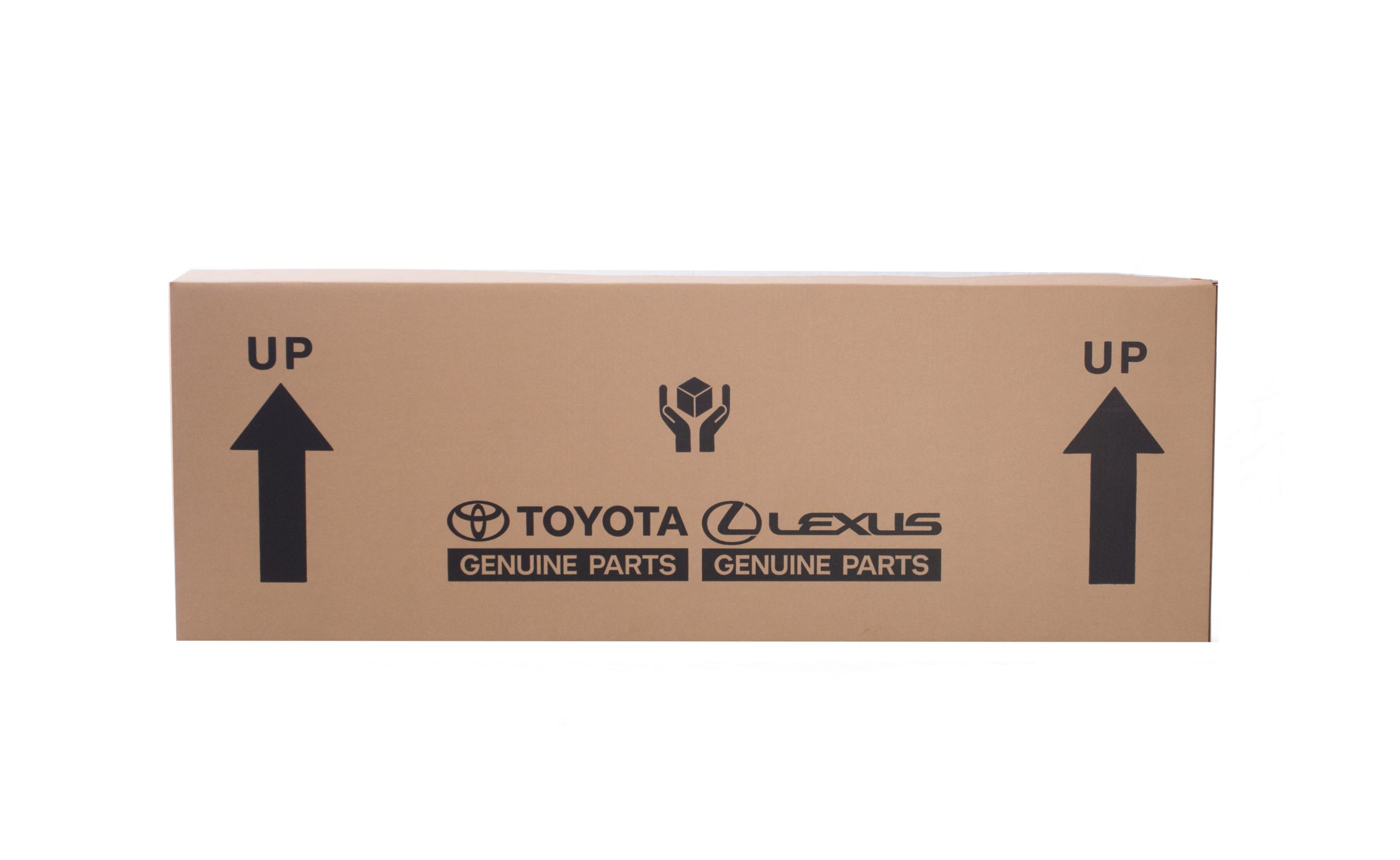

Custom packaging for auto parts

Custom Packaging for Auto Parts: Because Bubble Wrap Can’t Fix a Crankshaft

Let’s face it—automotive parts aren’t exactly known for their charm. They’re heavy, oddly shaped, and have more sharp edges than a bad haircut. So why are so many of them still being shipped in one-size-fits-all boxes with enough bubble wrap to fill a garage?

At Paramount Container, we believe your auto parts deserve better. That’s why we create custom packaging solutions designed to protect your products like a seatbelt protects a hot cup of coffee on a bumpy road.

We get it. You’re not just shipping widgets—you’re shipping precision-engineered components that need to arrive looking and functioning like they just rolled off the assembly line. And no, “toss it in a box and hope for the best” is not a strategy.

Here’s how we keep your parts safe (and your logistics manager sane):

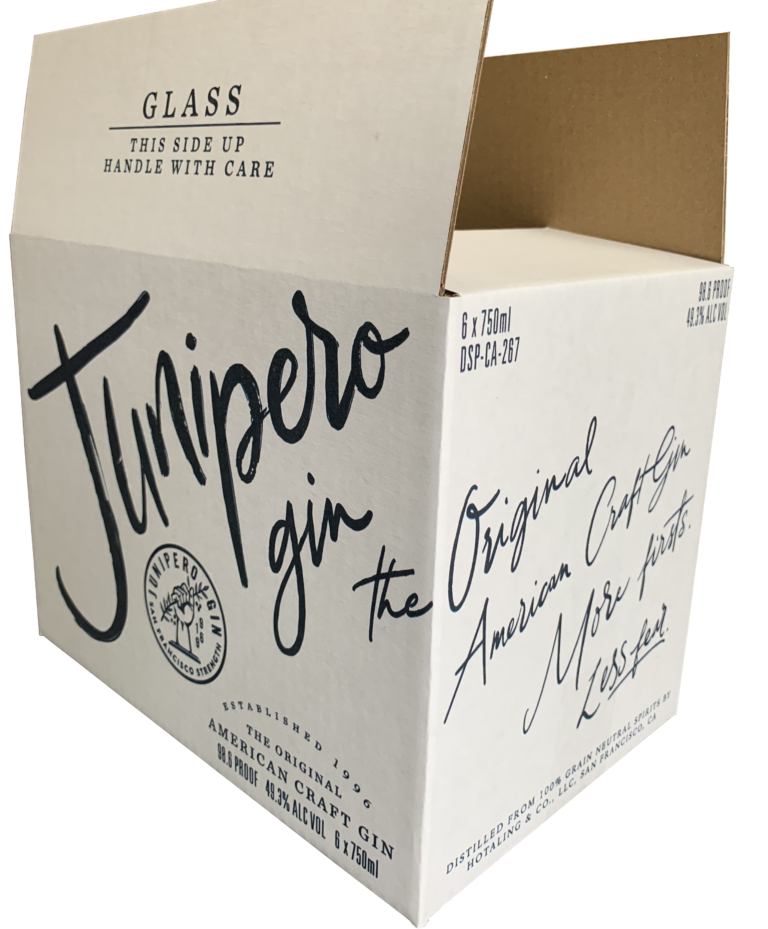

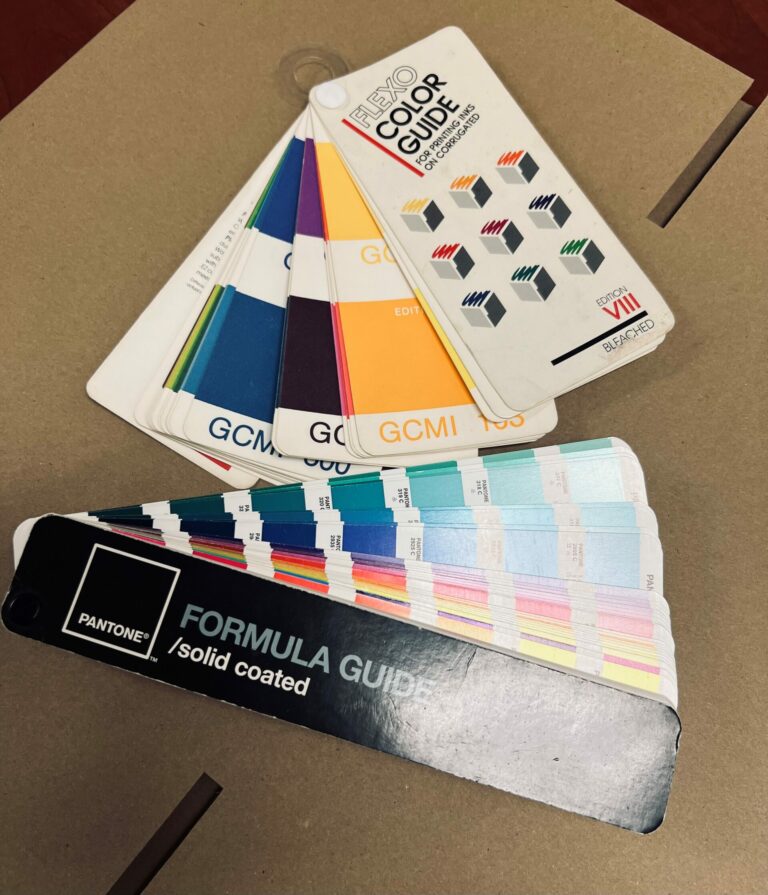

• Tailored Design: Our engineers use high-tech wizardry (a.k.a. CAD software) to design packaging that fits your parts like a glove. A strong, shock-resistant glove.

• Smart Materials: Foam inserts? Anti-static trays? Cardboard Inserts? We’ve got more options than a luxury car’s dashboard.

• Sustainable Solutions: Save the planet and your profit margins with eco-friendly packaging that’s built to last—or recycle.

• Rigorous Testing: We put your packaging through its paces with drop tests, vibration tests, and other scientific-sounding things to make sure it survives the supply chain jungle.

So whether you’re shipping tailgates or tailpipes, remember: custom packaging isn’t just a box—it’s the first layer of quality control.

Ready to upgrade from duct-taped desperation to packaging that actually works? Give us a call 714-257-1445. Let’s build something that keeps your parts safe and your customers impressed.