GCMI ink vs PMS Ink

When it comes to corrugated packaging, there are various factors that contribute to its overall visual appeal and quality. One crucial element in this process is the choice of ink used for printing on these packages or boxes. The two most commonly used ink systems are GCMI (General Converting Matched Inks) and Pantone inks.

GCMI inks are specifically designed for the packaging industry or corrugated box printing and cater to specific color standards required by converters. These inks come with a set range of colors that have been formulated to meet the unique demands of different types of packaging materials, mostly corrugated boards.

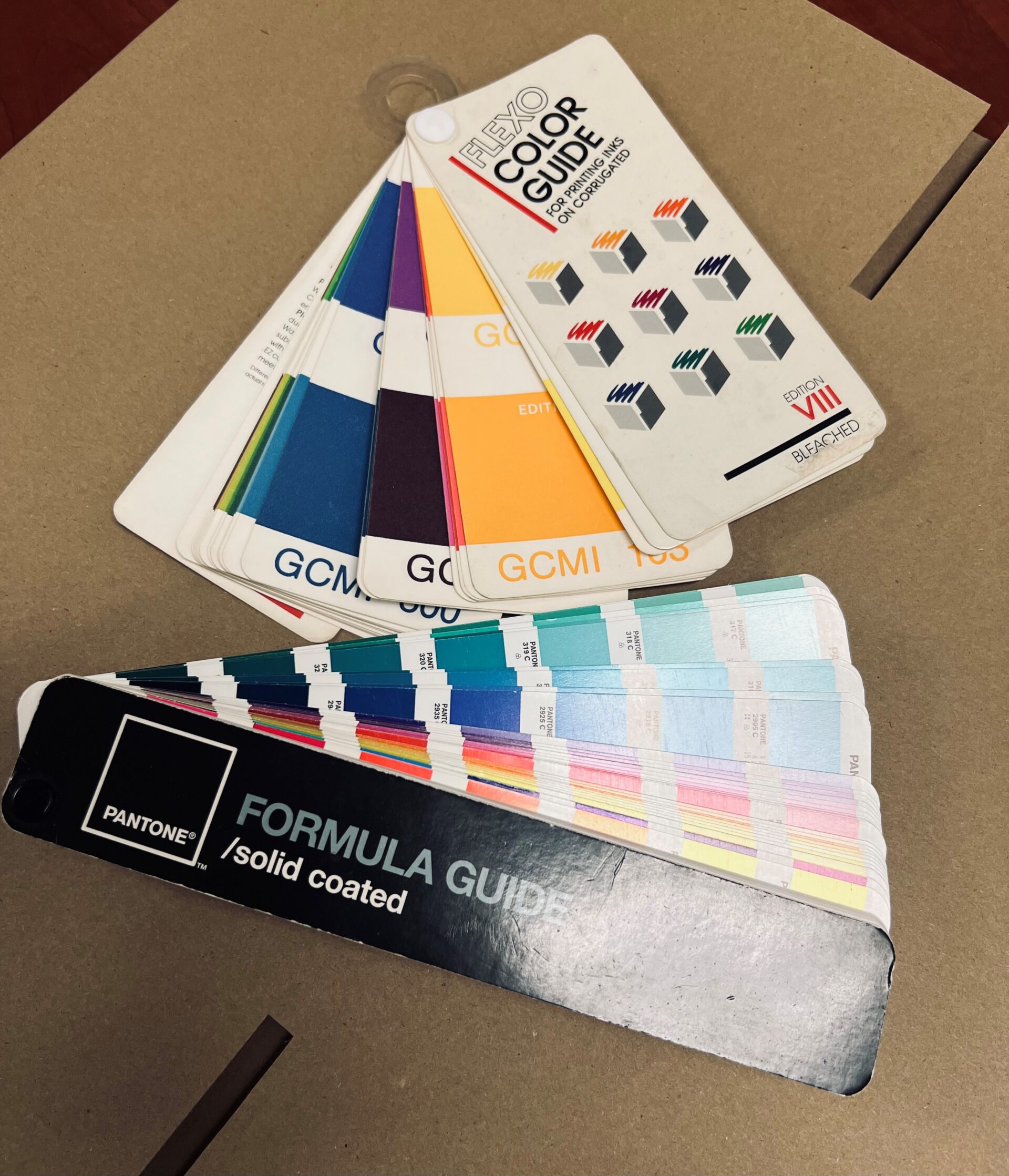

On the other hand, Pantone inks offer a wider selection of colors across multiple industries such as graphic design, fashion, and product development. Pantone has become an industry standard for color matching due to their extensive library which consists of thousands of hues. As opposed GCMI may have 10 blue inks, Pantone may have 300 choices.

So what sets these two ink systems apart when it comes to corrugated packaging?

Firstly, let’s consider versatility. While GCMI offers a limited range of colors tailored specifically for converting processes like flexographic printing on corrugated boxes, Pantone provides a much broader spectrum of shades suitable for various applications beyond just packaging.

Additionally, consistency plays a significant role when deciding between GCMI and Pantone inks. As GCMI is specially formulated for converting processes on specific substrates like corrugated board, it ensures consistent results from batch to batch within its designated color range. This level of consistency can be crucial when maintaining brand identity or ensuring uniformity across large production runs.

Pantone takes consistency one step further with their standardized swatch books known as “Pantone Matching System” (PMS). Designers using PMS can communicate exact color specifications effectively throughout different stages – from concept development through final production – ensuring accurate replication regardless of the technology or material being used.

Another aspect worth considering is availability. Since GCMI is primarily targeted towards the packaging industry, it is readily available from ink suppliers who specialize in converting processes. This accessibility makes it a convenient choice for corrugated packaging manufacturers.

On the other hand, Pantone inks are widely used across various industries such as printing, fashion, and design. These inks can be sourced from specialized suppliers or even mixed by printers themselves to achieve specific colors not found within standard swatch books. At Paramount Container we have an ink kitchen that can custom design an ink for your compan y or brand.

y or brand.

Ultimately, when choosing between GCMI and Pantone inks for corrugated packaging, several factors need to be considered – including desired color range, consistency needs, versatility requirements beyond packaging applications or brand guidelines – along with the ease of access to these ink systems.

Whether one opts for GCMI due to its tailored focus on converting processes or chooses Pantone’s extensive library of colors for broader application possibilities, both options offer unique benefits that cater to different priorities within the world of corrugated packaging.