ECT vs Virgin Liner

When it comes to packaging materials, one often encounters terms such as ECT paper and virgin liner in reference to corrugated boxes. These two types of liners play a crucial role in determining the strength and durability of the final product, but what exactly sets them apart? Let’s delve into the world of corrugated box production and explore the differences between ECT paper and virgin liner.

To understand these distinctions, we must first grasp the basics of corrugated boxes. These boxes consist of three layers: an inner layer called fluting sandwiched between two outer layers known as liners. The purpose of these liners is not only to provide protection but also to contribute to overall structural integrity.

ECT (Edge Crush Test) paper is a popular choice for corrugated box manufacturing due to its exceptional strength-to-weight ratio. It is made from recycled fibers that undergo various processes before being transformed into sturdy liner material. The term “Edge Crush Test” refers to a test method used by manufacturers to measure how much pressure or weight per unit area can be applied on a sample board before it collapses or loses its shape. This test determines the quality and resilience of ECT paper used as box liners.

On the other hand, virgin liner – as its name suggests – is made from 100% pure wood pulp without any recycled content. This pristine material offers distinct advantages when it comes to appearance, cleanliness, hygiene requirements, and even performance characteristics like printability or smoothness.

One key difference between ECT paper and virgin liner lies in their composition itself; while ECT paper utilizes recycled fibers, virgin liner solely relies on fresh wood pulp sourced directly from trees grown specifically for this purpose. Consequently, this distinction affects both environmental considerations surrounding sustainability practices within manufacturing processes as well as overall product performance attributes.

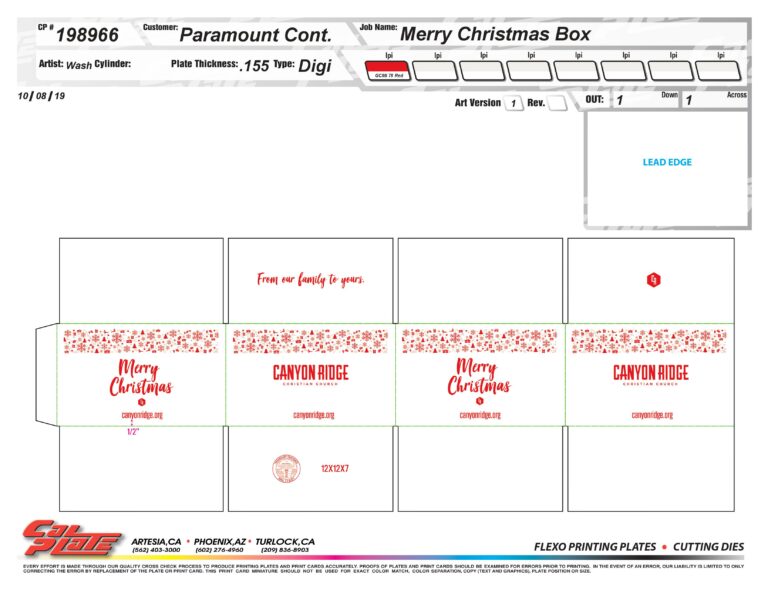

Additionally, because they are derived from different sources with varying degrees of processing involved during production stages (such as bleaching), there may be variations in color, texture, and even printability between ECT paper and virgin liner. These differences can influence the visual appeal of packaging materials depending on specific branding or marketing requirements.

Moreover, the choice between ECT paper and virgin liner also depends on the intended use of corrugated boxes. If a product requires high strength to withstand heavy loads or stacking pressure during transportation, ECT paper is often preferred due to its excellent crush resistance properties. On the other hand, when aesthetics or hygiene factors are paramount – for instance, in industries like food packaging or luxury goods – virgin liner may be more suitable due to its clean appearance and smoother surface finish.

In conclusion, while both ECT paper and virgin liner serve as important components within corrugated box production processes, they differ significantly in terms of their composition, environmental impact considerations, performance attributes (such as strength-to-weight ratio), visual appearance characteristics (color/texture/printability), as well as suitability for specific applications based on load-bearing requirements or hygienic standards.

Understanding these distinctions allows businesses to make informed decisions when selecting appropriate packaging materials that align with their needs while considering factors such as sustainability goals and consumer preferences. Whether it’s choosing cost-effective yet robust options through ECT paper liners or prioritizing immaculate presentation using virgin liners’ premium qualities – each has its place within the diverse world of corrugated box manufacturing.