-

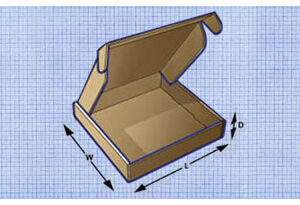

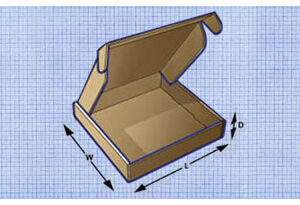

We produce a vast selection of die cut boxes. Die cut boxes can be used for shipping, retail, mailers, product displays, and more. The most common are Roll End Tuck Tops (RETT), we can also do auto or snap lock bottoms. Many other styles include RTE Reverse Tuck End, STE Standard Tuck End, RET Roll…

-

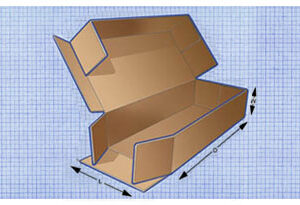

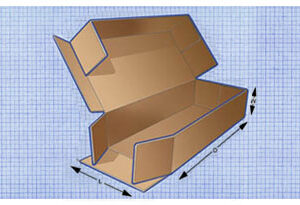

A single cut and scored piece features a fifth panel used as the closing flap, which completely covers one panel. Commonly used for narrow, long, or oversized products. The several layers of board provide stacking strength and protection.

-

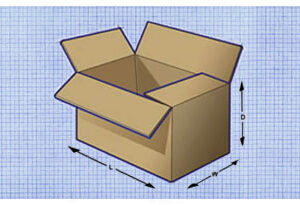

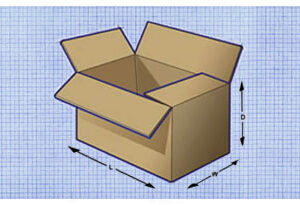

All flaps have the same length. When closed, the outer flaps come within one inch of complete overlap. The style is especially resistant to rough handling or shipping. The overlapping flaps provide added cushioning and thickness.

-

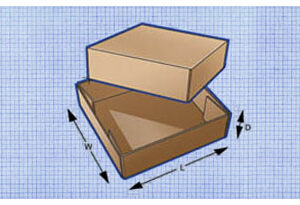

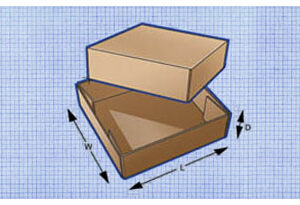

The FTD is two design style trays one slightly larger to completely overlap the bottom tray. Many companies also use a individual design style tray as a lid, end cap, or storage box.

-

Same as a Regular Slotted Container without one set of flaps. Commonly used as a storage box for easy access to product.

-

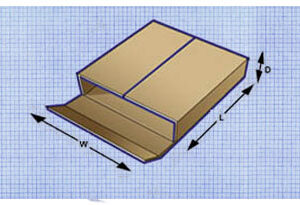

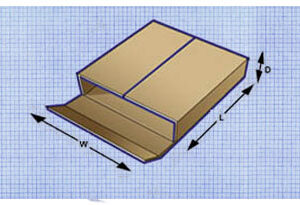

One piece of board is cut so that it provides a flat bottom, with flaps forming the sides and ends, and extensions of the side flaps meeting to form the top. We can also make the OPF with a partial overlap or with self-locking tabs.

-

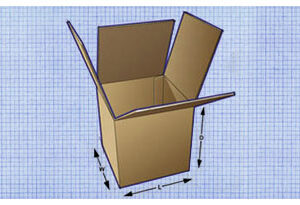

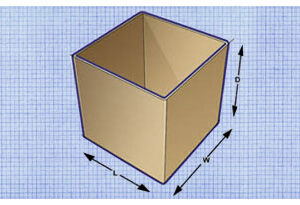

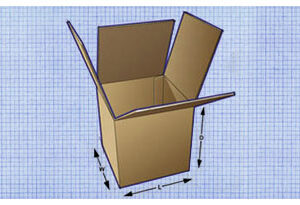

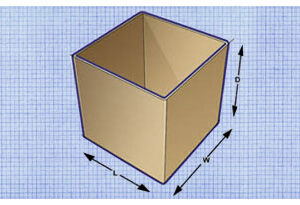

The most common box style we manufacture. The regular slotted container is the most popular shipping box in the world. It has 4 flaps on the top and bottom, where the outer (length) flaps meet at the center of the box.

-

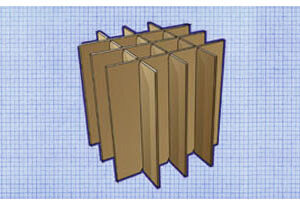

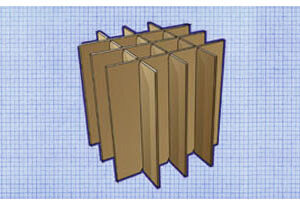

Dividers are used to separate items within a box. Dividers are especially suited for packaging fragile contents (bottles, candles, etc.). We can also produce these dividers in chipboard/paperboard assembled or unassembled.